How To Calculate Duct Size: A Comprehensive Guide

Learn how to calculate duct size effectively with h2x's comprehensive guide below. Optimise airflow and efficiency within HVAC systems!

Understanding how to calculate duct size for your HVAC system is crucial for ensuring efficiency, performance, and longevity.

In this guide, we will cover the importance of accurate duct sizing, the consequences of incorrect sizing, an overview of typical sizes, and detailed formulas and examples for circular and rectangular ducts.

Calculate Duct Size Introduction

Duct sizing plays a crucial role in heating, ventilation, and air conditioning (HVAC) system design and installation.

Correctly sized ducts facilitate optimal airflow, enhancing system efficiency and ensuring comfort.

This article explores the essentials of duct sizing, highlighting its significance and offering practical formulas and examples to calculate duct sizes accurately.

The Importance of Calculating Duct Sizes

Proper duct sizing is essential for several reasons.

- Firstly, it ensures your HVAC system runs efficiently, thereby conserving energy and reducing costs.

- Additionally, correctly sized ducts distribute air evenly throughout your space, maintaining consistent temperatures and enhancing comfort.

- Moreover, it minimises wear and tear on your HVAC system, extending its lifespan.

What Could Go Wrong If Sized Incorrectly?

Incorrectly sized ducts can lead to numerous problems.

Additionally, oversized ducts may result in poor air distribution and temperature inconsistencies, whereas undersized ducts can cause increased noise, reduced system efficiency, and even premature system failure.

Inefficient energy use from improper sizing can also lead to higher utility bills.

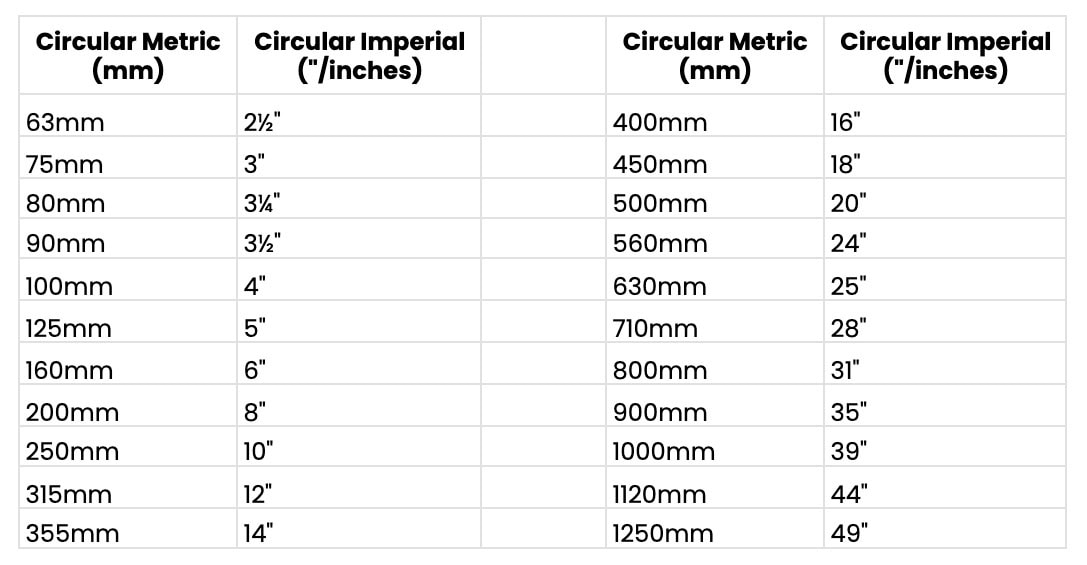

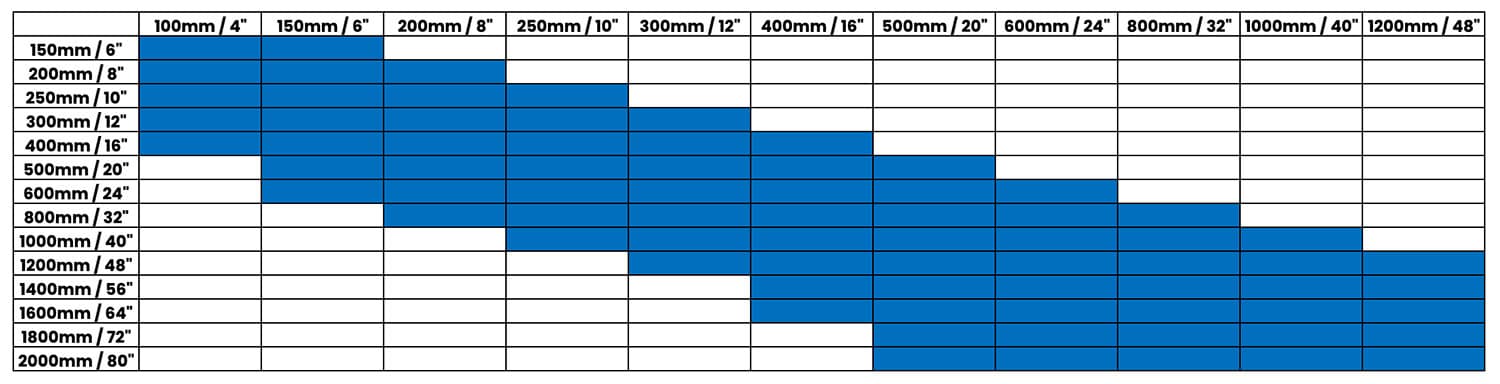

Typical Duct Sizes

Duct sizes vary widely based on the building’s size, layout, and specific duct system requirements.

Circular:

Rectangular:

Duct Size Formula & Calculation Example

Typically, sizing is based on both a maximum velocity and a maximum drop in pressure per meter.

Therefore, you must perform both calculations.

Sizing Based on Velocity:

The formula for this is:

Area (m²) = Flow rate (m³/s) / Maximum Velocity (m/s)

Lets say the main ducts that are supplying 29 L/s (0.029 m³/s) with a max velocity of 4 m/s, the required area will be:

Area (m²) = 0.029 m³/s / 4 m/s

Area = 0.00725 m² / 72.5 cm²

Now we know that we need an area of 72.5 cm²

Circular Duct Sizing

Diameter = 2 * √ 0.00725 m² / 3.14

D = 2 * 0.04805

D = 0.096 m / 9.6 cm / 96 mm

Therefore, a round duct must be at least 96 mm in diameter.

Rectangular Duct Sizing

Height = 0.00725 m² / 0.1m (assumed)

Height = 0.0725 m / 7.25 cm / 72.5 mm

Therefore, a rectangular duct must be at least 100mm x 72.5mm.

Sizing Based on Pressure Drop:

Next, we must check if that size will exceed the maximum pressure drop per metre.

We will go with a circular duct.

Firstly, let’s find the next largest available duct size – 100mm diameter.

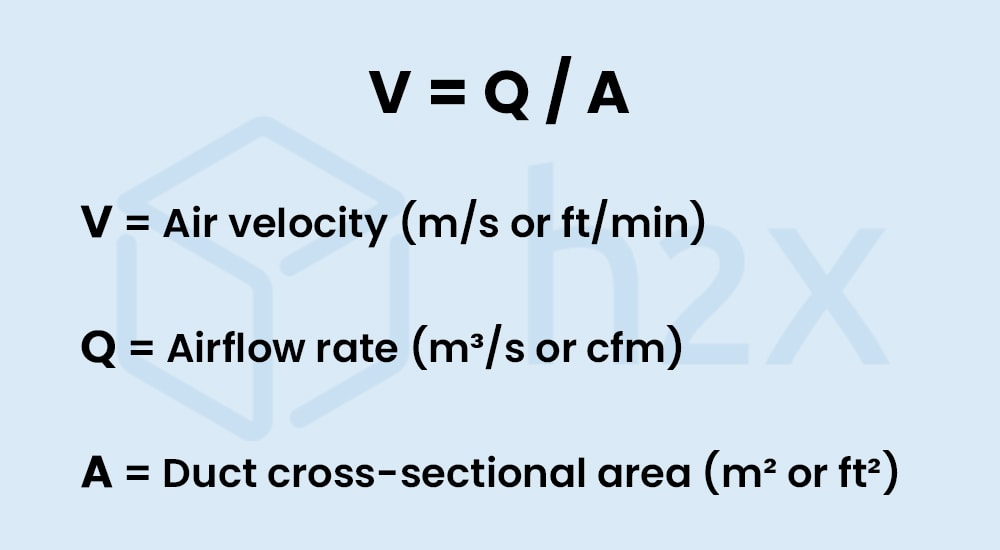

Calculate the Velocity

As the duct diameter has been increased to 100mm, we must recalculate the velocity, as it will be used for the pressure drop calculation.

Velocity formula:

Velocity = Q / A

Area formula:

Area = 3.14 * (d/2)²

A = 3.14 * (0.05)²

A = 0.00785 m²

Therefore, the velocity is:

Velocity = 0.029 m³/s / 0.00785 m²

V = 3.69 m/s

Calculate the Reynolds Number

To inform the drop in pressure, we also need to calculate the Reynolds number (Re), which uses this formula:

Reynolds number = Velocity * Diameter * Density / Viscosity

Re = (3.69 m/s * 0.1m * 1.2 kg/m³) / 1.8e-5 Pa.s.

Re = 24,600

Calculate the Friction Factor

We also need to calculate the friction factor (f) to inform the pressure drop.

friction factor = (0.11×((roughness coefficient/diameter) + (68/Re))^0.25) * 0.85 + 0.0028

friction factor = (0.11×((0.5/100) + (68/24600))^0.25) * 0.85 + 0.0028

f = (0.11×(0.005 + 0.00276)^0.25) * 0.85 + 0.0028

f = 0.03055

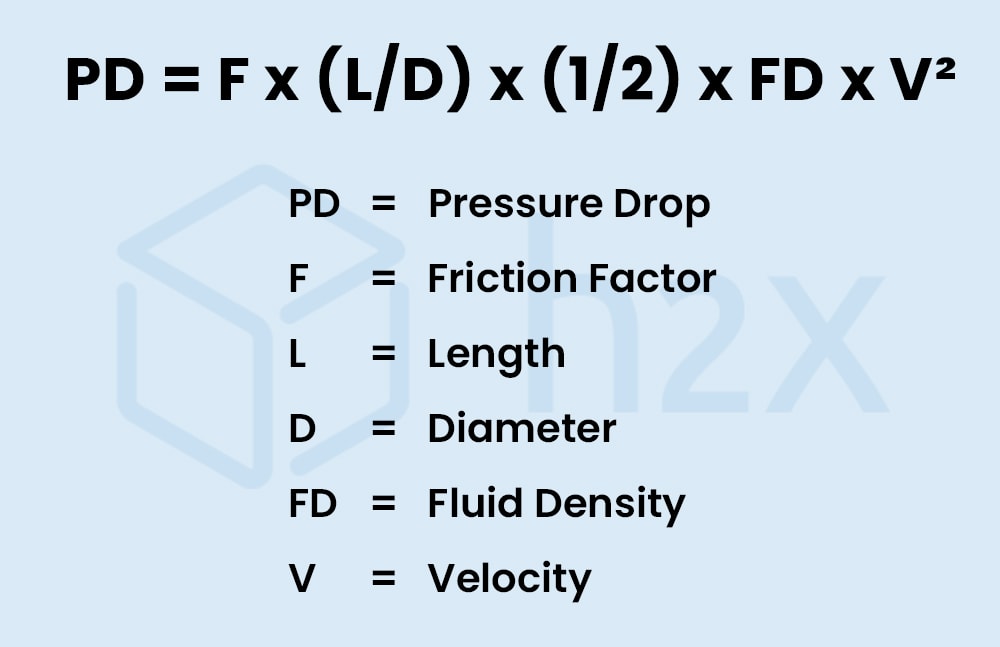

Calculate the Pressure Drop

The final step, is to check whether we lose more than 1 Pa/m.

The formula is:

Pressure Drop = f * (Length/Diameter) * (1/2) * fluid density * Velcoity²

PD = 0.03055 * 10 * 0.5 * 1.2 * 3.69²

PD = 2.5 Pa/m

For an efficient system, our maximum pressure drop per metre is 1 Pa/m.

Even though a 100mm duct can supply the flow rate at a velocity below 4 m/s, there will be too much drop in pressure.

Therefore, we must increase to the next duct size and redo the calculation.

Following the same process, a 150mm diameter duct has a pressure drop of 0.33 Pa/m.

Our duct size needs to be 150mm.

Conclusion

Accurate duct sizing is pivotal for the efficiency and effectiveness of your HVAC system.

It ensures optimal air flow, comfort, and energy-efficiency while preventing potential issues with incorrect sizing.

You can use the formulas and examples provided to calculate the correct duct size for your system, ensuring its long-term performance and sustainability.

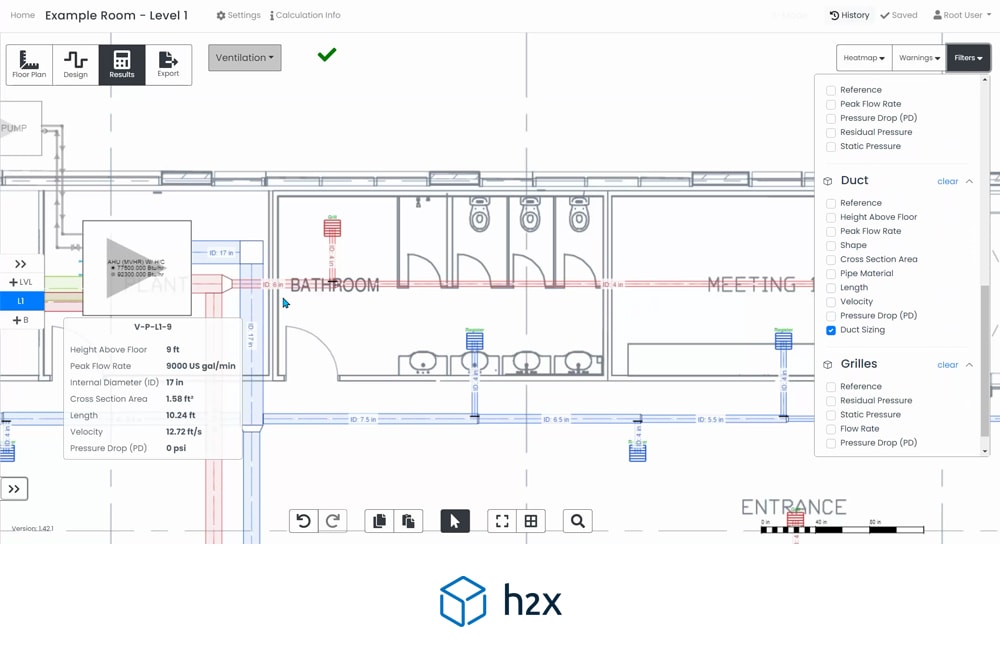

h2x Engineering is design software built to ensure compliance, efficiency, accuracy and collaboration.

Moreover, the tool streamlines engineering calculations for flow rate, velocity, pressure, pump duty, plant size, and recirculation systems.

This eliminates the need for complex math, enabling engineers to focus on project design and to save time.

Additionally, our software empowers engineers to efficiently develop high-quality designs while adhering to industry standards.

With millions of kilometers of pipes sized in projects globally, h2x is a trusted solution.

Book a demo or start a free trial with h2x today to discover how we can help you improve your design and calculation workflow!

Calculate Duct Size FAQs

What is the formula for calculating duct size?

The formula for calculating duct size often involves the airflow rate and the air velocity.

The cross-sectional area of the duct (A) can be found using the equation A = Q / V, where Q is the airflow rate and V is the air velocity.

Furthermore, the duct size can then be calculated.

What steps should be taken if the duct size is outside the recommended ranges?

If the duct size is outside the recommended ranges, it’s important to assess the entire duct system to identify why the discrepancy exists.

Consequently, rectifying the issue may involve resizing the ducts, adjusting the layout, or modifying duct systems components to ensure efficient operation and adequate air distribution.

Are there any industry standards for duct sizes?

Indeed, industry standards for duct sizes are typically established by organisations like DW144 or the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE).

These standards are based on extensive research and consider air velocity, pressure loss, noise level, and energy efficiency factors.

How does the duct size affect air velocity and system performance?

Duct size directly affects air velocity and system performance.

If ducts are too small, air velocity is too high, which can cause noise and reduce the efficiency of air distribution.

On the contrary, oversized ducts can result in low air velocity, leading to poor air mixing and potential issues with temperature regulation and stratification.

Properly sized ducts optimise air flow, ensuring efficient system performance and comfort.

What are common problems associated with incorrect duct sizes?

Common problems associated with incorrect duct sizes include increased noise, higher energy consumption, uneven heating or cooling, excessive wear on system components, and reduced overall HVAC system efficiency and lifespan.

Moreover, in extreme cases, incorrect duct sizing can lead to system failure or the need for substantial modifications.

What is the rule of thumb for HVAC duct sizing?

You should accurately calculate duct size.

Fortunately, there is a range of tools available, such as h2x, which make HVAC sizing both easy and accurate.

Duct Size Calculator:

How does duct size affect HVAC system noise and efficiency?

Duct size has a significant impact on HVAC system noise and efficiency.

Furthermore, undersized ducts can result in a whistling or whooshing sound due to high air velocity, whereas oversized ducts may cause low air velocity and reduced system efficiency.

Proper duct sizing balances air velocity to minimise noise and optimise air distribution for efficient system operation.

What is the method of duct sizing?

Duct sizing methods involve determining the necessary volume flow rate, considering the friction loss, and using a duct calculator or software to find the correct size of ducts.

What is a ductulator?

A duct size calculator (ductulator), essential for HVAC system design, calculates the dimensions of ductwork based on airflow rate and friction loss, ensuring optimal system performance.

What are the three methods of duct sizing?

There are three methods of duct sizing:

Firstly, equal friction maintains a constant drop in pressure per meter of the duct.

Secondly, static regain aims to balance pressure variations throughout the ductwork.

Lastly, velocity reduction reduces air velocity as it moves through larger spaces to minimise noise and wear.

h2x: All-In-One Tool for Calculating, Designing, Estimating, and Paperwork

What's in the Pipeline?

Get technical resources delivered to your inbox weekly!

Testimonials

What Installers Say

What Consultants Say

A game changer for the humble plumber. Incredible.

Brad Winkel

Director at Queenstown Plumbing

Brilliant, simple and easy to use. Game changer.

James Major

Director at Hubb

Big time game changer to the industry!

Viv Jude

Director at UHC

Incredible software! Super user-friendly and allows you to save so much time.

Devni Gamage

Engineer at DMA

h2x is great software, our company use it nearly every day. It is easy to use with direct conversion from h2x to Revit.

Callum Craig

Engineer at WDE

h2x is fantastic software. It is very easy to use and the ability to output to Revit is a fantastic time saver.

Joe Kirrane

Engineer at MEP